Choosing the right printing method for your branded merchandise can feel overwhelming. Get it right, and your products look sharp, professional, and perfectly on-brand. Get it wrong, and you could face blown budgets, missed deadlines, and merchandise that doesn't do your logo justice. So, how do you decide between the industry's two heavyweights: offset and digital printing?

Think of it this way: offset printing is your go-to for massive, high-quality runs where cost-per-item is king. Digital printing, on the other hand, is the agile champion of speed, flexibility, and small-batch orders. This guide will cut through the technical jargon to help you confidently choose the perfect method for your next project, ensuring you get the best quality, price, and turnaround time.

Choosing Your Printing Method: An Executive Summary

Picking the right printing technique doesn't have to be complicated. It all comes down to what you're trying to achieve. Are you gearing up for a massive giveaway at a national conference or putting together a small, targeted mailer for a handful of VIP clients? Each situation calls for a different strategy.

Getting a handle on the core strengths of each method is the first step. This quick overview cuts through the technical noise to give you a clear framework for making a smart decision. Before we dive into the nitty-gritty of technology and costs, this summary provides a bird's-eye view to help you see which path makes the most sense for your budget, quantity, and deadline. After all, the best promotional campaigns are built on these foundational choices. For more on this, check out our guide on how to increase brand awareness.

Quick Decision Table: Offset vs. Digital Printing at a Glance

If you're in a hurry, this table is the fastest way to see which printing method is the right fit for your project's immediate needs.

| Factor | Offset Printing | Digital Printing |

|---|---|---|

| Best For | High-volume orders (typically 500+ units) where consistency is key. | Small to medium-sized orders, rapid prototyping, and personalized items. |

| Cost Structure | High initial setup cost, but a very low cost per unit on large runs. | No setup cost, but a higher, flat cost per unit regardless of quantity. |

| Turnaround Time | Slower due to plate creation and press setup (days to weeks). | Much faster, with some projects completed the same day or within 24-48 hours. |

| Color Fidelity | The gold standard for perfect Pantone® (PMS) color matching. | Excellent CMYK color reproduction; Pantone matching is simulated and can vary. |

| Customization | Not suitable for personalization; every print is identical. | Ideal for variable data printing (e.g., individual names, QR codes). |

This table gives you the essentials, but as you'll see, the real magic is in the details. The best choice often depends on the specific product you're branding and the impression you want to make.

Understanding The Technology Behind Each Print

To really get a feel for whether offset or digital printing is right for your project, it helps to understand what's happening behind the curtain. While both can give you beautiful results, the way they get there is completely different—and that difference impacts everything from cost to timeline. Think of one as a time-tested industrial powerhouse and the other as a nimble, modern specialist.

Let's break down how each one works. Knowing the fundamentals makes it crystal clear why offset is built for massive, identical runs and why digital excels at speed and flexibility for smaller, custom jobs.

The Classic Method: Offset Printing Explained

Offset printing, sometimes called lithography, is the traditional workhorse of the commercial printing world. It’s an indirect process where ink isn't applied directly from a design plate to the final product.

First, your design is etched onto a set of custom metal plates—one for each color (cyan, magenta, yellow, and black, plus any specific Pantone colors). These plates are mounted onto a massive printing press.

Once set up, the process is pure mechanical precision:

- Inking the Plate: Ink rollers apply ink to the plate, which only adheres to the etched parts of your design.

- Transfer to Blanket: The inked image is then transferred, or "offset," from the metal plate onto a soft rubber blanket.

- Printing onto Surface: Finally, that rubber blanket presses the image cleanly onto the material.

This setup is labor-intensive, explaining the higher upfront costs. But once the press starts rolling, it can churn out thousands of identical copies with incredible speed and unmatched quality, causing the per-item cost to plummet.

The magic of offset printing is its unwavering consistency. After the setup, the first print and the ten-thousandth print are perfect, color-matched replicas. It's a machine built for scale and perfection.

The Modern Approach: Digital Printing Uncovered

Digital printing works a lot like a high-end office printer, just scaled up for industrial use. It takes your digital file—like a PDF or AI file of your logo—and prints it straight onto the promotional item. There are no plates, no rubber blankets, and no complex setup.

This direct-to-surface method is what makes digital so fast and flexible. Want a full-color photo on a notebook? The file is sent directly to the printer. This streamlined process opens up a ton of creative options, which you can explore in our guide on how to put a logo on a notebook.

The technology lays down tiny dots of ink or toner to build the image. Because there are no physical plates to change, every single item can be unique. This is what enables variable data printing, where you could print a different name on each piece of merchandise. The two main technologies you'll encounter are inkjet and laser; getting familiar with the Laser vs. Inkjet debate can give you a deeper understanding.

A Practical Cost Breakdown For Your Merchandise

When deciding between offset and digital printing, price is often the first consideration. But the real story is in how each method is priced. Getting a handle on this dynamic is the key to making a smart financial choice for your branded merch.

Think of it this way: digital printing is straightforward, with a simple, flat cost per item. Offset printing has a hefty upfront setup fee, but your cost-per-item drops dramatically the more you print.

The Upfront Investment of Offset Printing

Offset printing is all about economy of scale. The biggest cost is front-loaded into the setup: creating custom metal plates and calibrating the press. That process is the same whether you’re printing 500 notebooks or 50,000.

This is why an initial quote for a small offset job can cause sticker shock. But once that press is running, the actual cost to print each additional item is incredibly low. This is where volume saves you a ton of money.

Think of offset setup costs as a fixed investment. The more items you print, the more you spread that cost out, which makes the price per piece plummet. It’s the undisputed champion for large-scale production runs.

The Steady Price of Digital Printing

Digital printing skips that elaborate setup. There are no plates to make and calibration is minimal. You can go from a digital file to a finished product almost instantly with virtually zero setup cost.

This gives you a consistent, predictable price for every single item. The price for your first custom pen is the exact same as the price for your 200th. This model makes digital printing a fantastic and affordable option for small businesses, startups, or anyone needing a smaller batch of promotional gear. For more tips on making your budget work, check our guide on finding discounts on promotional products.

Finding Your Economic Breakpoint

So, at what point does it become cheaper to go with offset instead of digital? This "breakpoint" can shift, but a solid rule of thumb is around 500 to 1,000 units.

-

Scenario A: The Workshop Giveaway You need 100 branded notebooks for a client workshop. Digital printing is the clear winner. The per-unit cost will be fair, and you avoid the big setup fee.

-

Scenario B: The National Campaign Your company needs 10,000 branded tote bags. Offset printing is the only path that makes sense. The cost per bag will be a tiny fraction of what digital could offer.

Even with advances in digital, offset printing still holds a commanding position for large-scale jobs. In fact, the global market for offset lithography was projected to hit USD 310.9 billion by 2025, proving its ongoing dominance where high volume and cost-efficiency are non-negotiable.

Getting Color and Finish Right: Protecting Your Brand's Identity

Your brand's color isn't just a design choice; it's a non-verbal promise of consistency. It’s what makes your logo pop and your merchandise instantly recognizable. When choosing between offset and digital printing, getting the color and finish right is everything.

This is about ensuring the specific shade of red on your tote bags exactly matches the one on your notebooks and your website. Let’s dig into how each printing method handles this crucial task.

Offset Printing: The Gold Standard for Color Precision

When your brand color has to be perfect—no exceptions—offset printing is the only way to go. It's the champion of color accuracy because it relies on the Pantone Matching System (PMS). Think of PMS as a universal recipe book for color; each shade has a precise formula.

Instead of mixing dots on the page, offset printing uses pre-mixed inks to those exact Pantone specifications. If your brand guide dictates "Pantone 186 C," that’s the literal ink that gets loaded into the press. The result? Flawless, identical color on every item.

Offset printing's use of pure Pantone inks eliminates color variation. It’s not an approximation; it’s the exact color, every time. This is the cornerstone of true brand color consistency.

Offset also unlocks a world of premium finishes:

- Metallic and Fluorescent Inks: Add a shimmer of gold or a pop of neon.

- Varnishes and Coatings: Apply a targeted spot gloss to make a logo shine or a soft-touch matte finish for a sophisticated feel.

These options elevate your branded products from simple giveaways to memorable, tactile experiences.

Digital Printing: Vibrant Images and Unmatched Flexibility

Digital printing approaches color from a different angle. It uses a four-color process called CMYK (Cyan, Magenta, Yellow, and Key/Black). By layering microscopic dots of these four inks, digital printers can create a massive spectrum of colors, making them excellent for full-color photographs or complex graphics.

While digital printing simulates Pantone colors rather than using pure inks, the technology has come a long way. Modern digital presses can now accurately reproduce an impressive 96% of Pantone colors, making the results visually indistinguishable for most projects.

The real magic of digital lies in its agility. If you need a small run of business cards with a vibrant, full-color logo, digital is your best friend.

Making the Call: When to Use Each Method

How do you choose? It boils down to your project's needs.

- Choose Offset Printing If: Your brand identity depends on one or two specific Pantone colors, you need absolute color consistency across a large order, or you want special finishes like metallic inks.

- Choose Digital Printing If: Your design is a full-color photograph or has complex gradients, you need a small-to-medium quantity and can accept a very close Pantone match, or you're on a tight deadline.

Both methods produce stunning results. By understanding their unique strengths, you can make an informed decision that aligns with your brand standards.

How Speed and Volume Shape Your Project

When planning a merchandise order, two questions are always front and center: "How fast can I get this?" and "How many do I have to order?" The answers almost always point you to either offset or digital printing.

It’s like deciding between a custom-built car and a high-performance model off the lot. One offers precision for a massive rollout but takes time. The other delivers speed and flexibility for immediate needs. Getting this trade-off right is key.

Digital Printing: Built for Speed and Agility

Digital printing is perfectly suited for today's fast-paced marketing world. Since it prints directly from a digital file, there are no plates to create. This means turnaround times are often measured in days, not weeks.

This speed makes digital the clear winner for any urgent project. Need 150 branded pens for a trade show next week? Digital handles these requests without breaking a sweat.

Digital printing’s superpower is its on-demand nature. It’s perfect for turning around small to medium-sized orders quickly, making it a lifesaver for time-sensitive projects or just-in-time inventory.

With no real setup costs, there are effectively no minimum order quantities (MOQs). This is huge for startups or campaigns where you want to test a design first. You can easily order a small batch of 50 custom notebooks without getting stuck with a mountain of inventory. Check out our guide on finding cheap pens in bulk for more ideas.

Offset Printing: Made for Scale and Careful Planning

Offset printing plays a different game. The process is more involved—creating plates, calibrating a press, and mixing inks all takes time. This is what's required to achieve incredible quality and cost-efficiency at a massive scale.

This method is designed for large, planned-out campaigns. If you need 20,000 tote bags for a nationwide promotion, offset is the only way to go. The high initial setup cost is absorbed by the rock-bottom price per bag, and the longer lead time is simply baked into the schedule.

Because of that setup, offset printing always comes with a high minimum order quantity, usually starting around 500 or 1,000 units. This makes it a poor fit for small projects but perfect for building up a stable supply of core merchandise.

Recent data from an industry analysis on PIworld.com shows that 57% of printers who adopt high-speed inkjet technology are doing it specifically to migrate offset work, highlighting the industry's shift toward integrated digital workflows for faster results.

Making The Final Decision For Your Brand

Choosing between offset and digital printing comes down to matching your project's needs with the right tool. We've seen how one is a workhorse for large-scale production, while the other delivers speed and flexibility. Let's pull it all together so you can make the best choice.

This isn't about which method is "better" overall; it’s about which one is better for you, right now. The right answer is different for a startup needing a small run of pens versus a corporation planning its promotional calendar a year in advance.

Synthesizing Your Project Needs

To get this right, you have to balance four critical variables: your budget, the volume you need, how fast you need it, and the level of quality you’re aiming for.

A tight deadline combined with a need for personalization almost always points to digital printing. On the flip side, if your main goal is the absolute lowest cost per item on an order of thousands of notebooks, offset printing is the clear winner every time.

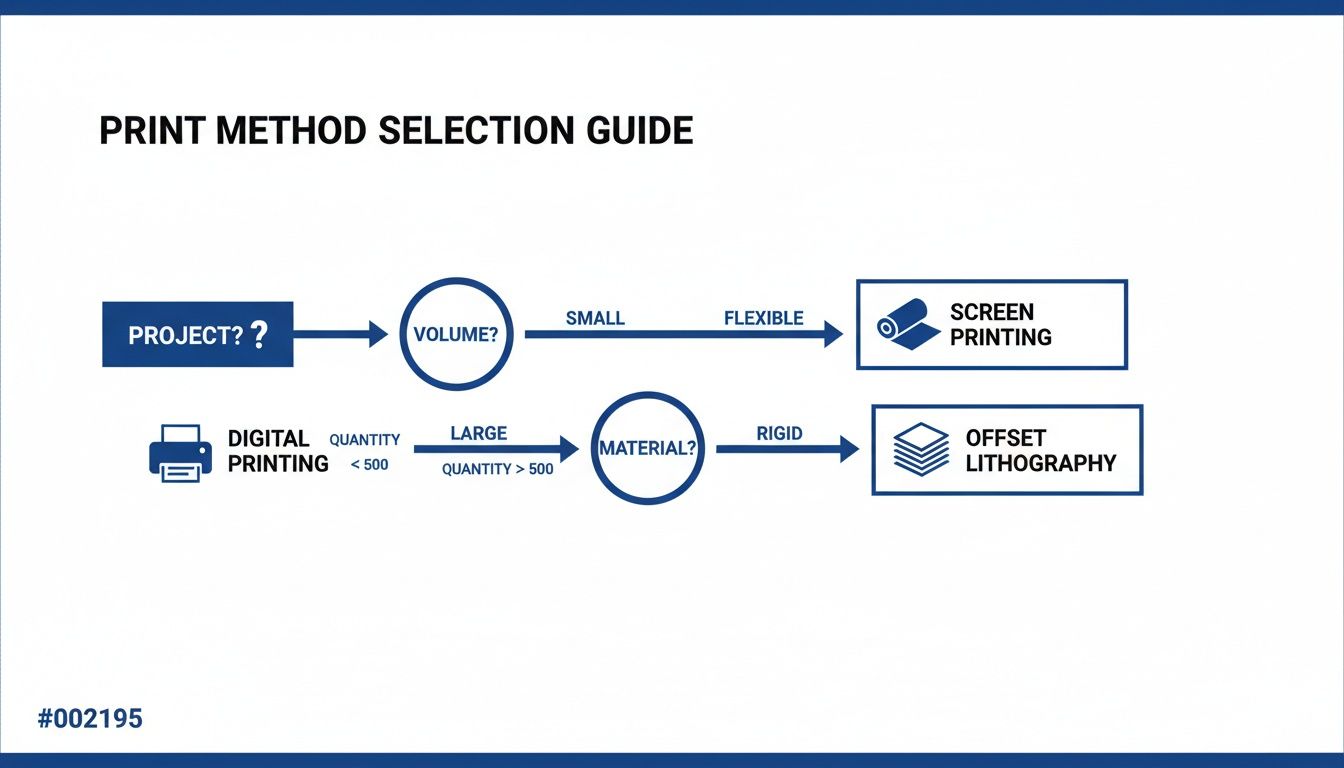

This decision tree helps visualize how project volume is a primary factor in the offset vs digital printing debate.

As you can see, large-volume projects naturally lean toward offset to maximize cost efficiency. Smaller, more urgent orders are almost always better suited for digital’s nimbleness.

Final Decision Checklist: Which Method Suits Your Project?

Still on the fence? Use this checklist to run through the most important factors for your next promotional product order.

| Consideration | Choose Offset If... | Choose Digital If... |

|---|---|---|

| Order Volume | You need 500+ units of the exact same design. | Your order is for fewer than 500 units. |

| Budget Strategy | Your goal is the absolute lowest cost-per-item on a large run. | You need to minimize upfront costs and have no setup budget. |

| Project Timeline | You have a flexible timeline of several weeks for production. | Your deadline is tight, and you need a turnaround in a few days. |

| Color Requirements | Your brand guidelines demand an exact Pantone (PMS) color match. | A close color approximation using CMYK is acceptable for your design. |

| Customization Needs | Every item printed will be identical. | You need variable data, like different names or numbers on each item. |

The demand for faster, more personalized printing is driving huge changes. The digital printing market, valued at over USD 33 billion in 2025, is on track to hit USD 63.2 billion by 2035—a growth rate of 7.5% a year. This boom shows a major shift toward the flexibility digital provides. You can read the full research on the digital printing market to dive deeper into these trends.

The Bottom Line: Your choice hinges on a trade-off. Offset gives you unmatched cost efficiency and color perfection at scale. Digital gives you speed, flexibility, and affordability for smaller, more immediate needs.

Let’s Bring Your Vision to Life

Now that you're armed with the knowledge to choose with confidence, the next step is to see the quality firsthand. Nothing beats holding a physical sample to feel the finish and see how vibrant the colors look up close.

Our team at Persopens is here to guide you through these final steps. We can offer advice based on your specific project, send you samples of both offset and digitally printed products, and put together a detailed quote comparing your options.

Ready to get started? Contact our printing experts today for a free consultation and let's create branded merchandise that makes an impact.

Got Questions? Let's Get Them Answered.

Even after you've weighed the pros and cons of offset vs. digital printing, a few specific questions always pop up. Here are some straightforward answers to the questions we hear most often.

Can Digital Printing Really Match My Brand's Pantone Color?

The honest answer is: almost. Modern digital presses are incredible, able to simulate up to 96% of the Pantone library using a CMYK mix. For most eyes, the result is indistinguishable.

However, if your brand standards are ironclad and require a perfect match, offset printing is your only guarantee. It uses actual, pre-mixed Pantone ink. We always suggest getting a physical proof if you're considering digital for a color-critical project.

What’s the Magic Number Where Offset Becomes Cheaper?

There's no single magic number, but the tipping point is usually between 500 and 1,000 units.

Below that range, the high setup cost of offset doesn't make sense. But once you cross that threshold, the per-item cost of offset drops dramatically, delivering serious savings on bigger orders. Our team can run the numbers for your specific product to show you exactly where that breakpoint lies.

It really boils down to a simple volume calculation. Digital gives you predictable costs on smaller batches, while offset delivers unbeatable economy of scale as your order size grows.

Are There Eco-Friendly Choices for Both Methods?

Yes, absolutely. You don't have to compromise on sustainability.

- For Offset Printing: You can choose vegetable-based inks, water-based coatings, and paper from sustainably managed forests (look for FSC certification).

- For Digital Printing: The biggest green advantage here is reduced waste. There are no plates and fewer chemicals, making it a lean process. It also prevents overproduction.

Let us know your sustainability goals, and we can walk you through the most responsible options that fit your project and budget.

Ready to see how your design looks in person? The team at Persopens is here to help you lock in the perfect printing method for your promotional gear. Whether it's a small run of vibrant notebooks or a massive order of color-perfect pens, we’ll make sure your brand looks brilliant.

Explore our collection of custom promotional products at Persopens.com and get a free quote today!

0 comments